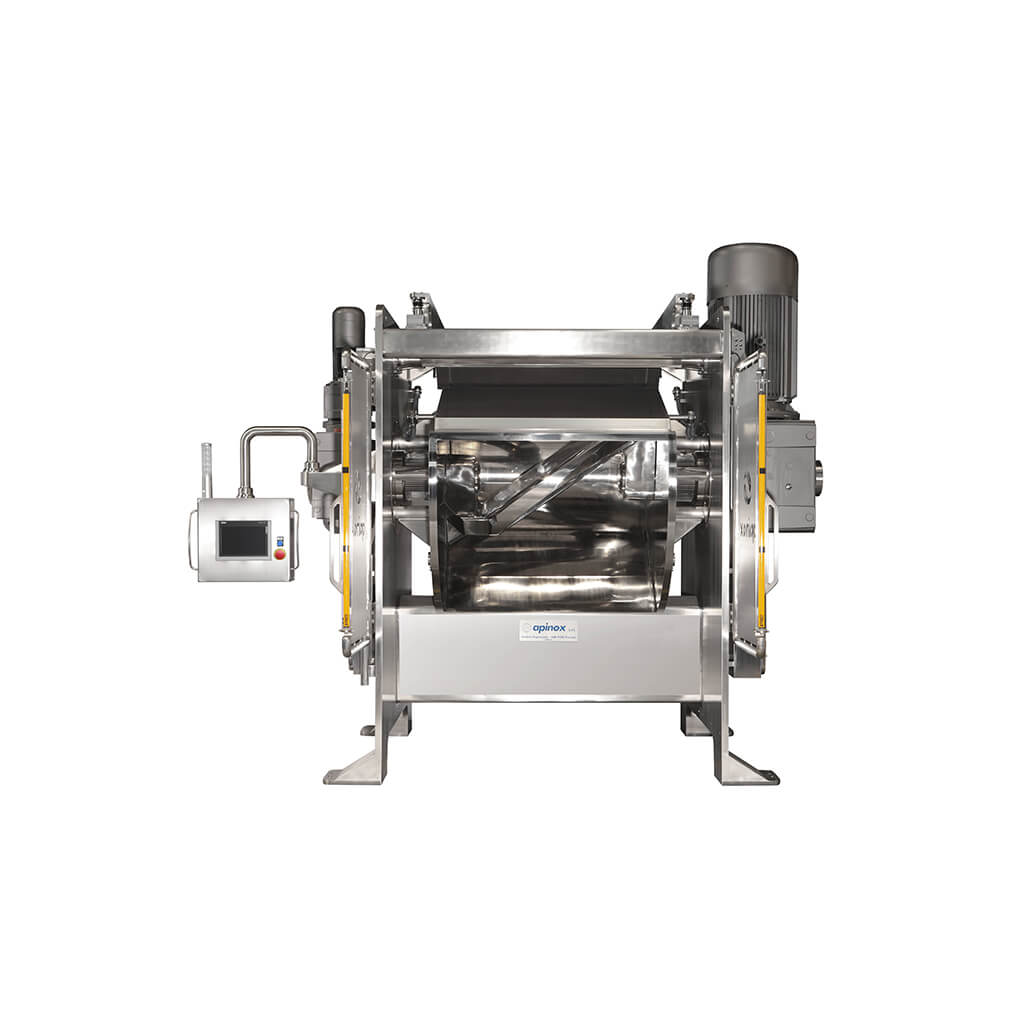

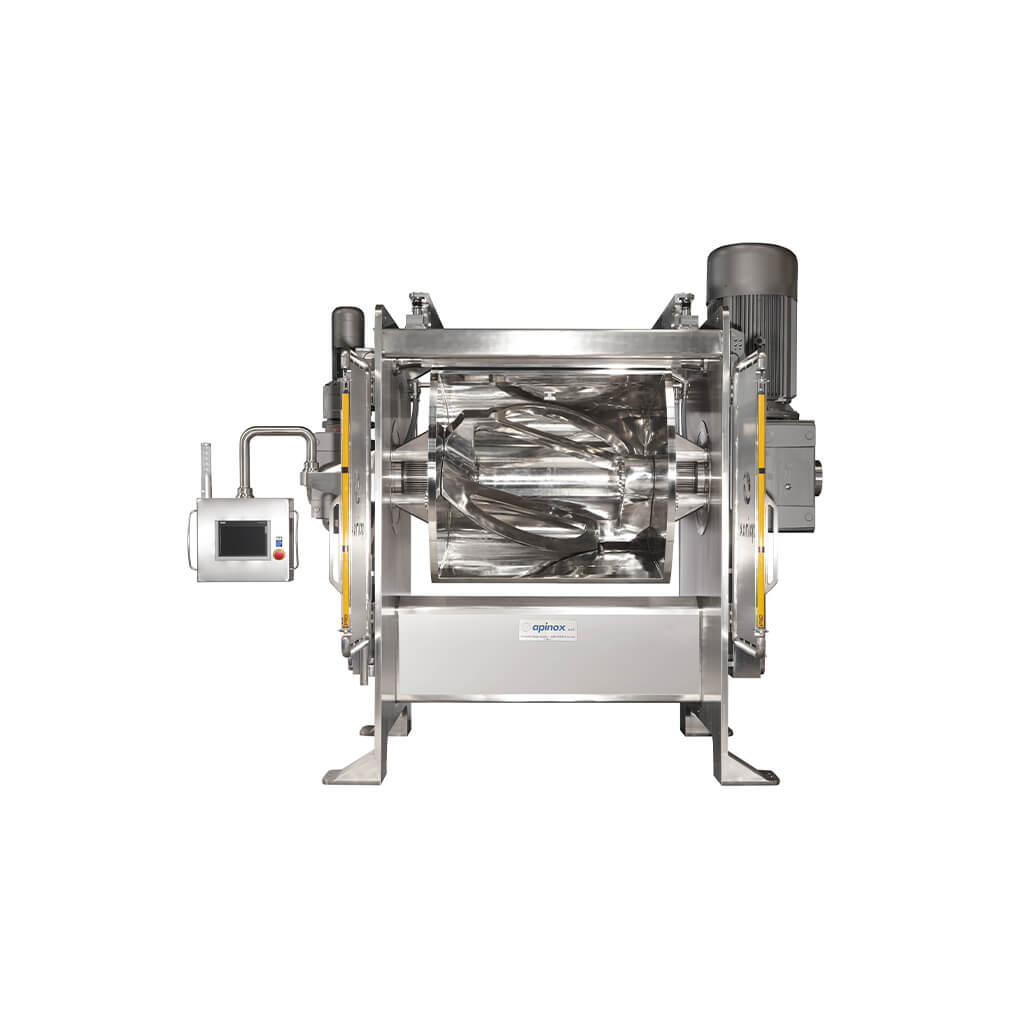

RMNL – Light Hygienic Design Single-Arm Horizontal Mixer

Industrial Mixer for Soft and Delicate Dough

The mixer type “RMNL” is a high-speed and high efficiency mixer, suitable only to produce soft and delicate dough. The product capacity of the mixer is related to the type of recipe used and to the automation degree of the raw material feeding system. With the mixer type “RMNL” it is possible to position, under the mixing bowl, a conveyor belt for the direct collection of the dough, thus allowing the automatization of the mixer’s work cycle and the continuous feeding of the production line.

Our mixer type RMN has some defining characteristics that distinguish it from the other horizontal mixers:

– complete stainless steel manufacturing;

– It is easy to clean and compatible with CIP cleaning systems;

– It is easy to inspect and to service, because there are no protection panels;

– It is easy to assemble and disassemble its components, because all the main parts are visible.

It has been designed and manufactured according to the hygienic design principles, in order to preserve the food safety and, at the same time, the operators’ safety. The front / rear opening of the mixing bowl – available as an option – allows to use both sides to discharge the product, both in a wheeled tub and onto a conveyor belt. It also allows the use of the rear side of the mixer for the manual loading of the micro-ingredients and for the internal cleaning of the mixing bowl. The available range for this type of mixer is from 150 kg/batch to 1800 kg/batch.

Applications

Available As An Option

FRONT AND REAR TILTING OF THE MIXING BOWL

Mixing bowl tilting on both sides, front at about 135°- rear at approx. 90°. Mechanical lifting of the cover, stroke approx. 10÷15 [mm].

SYSTEM FOR THE DRAINAGE OF CLEANING WATER FROM THE MIXING BOWL

System for the drainage of the cleaning water of the mixing bowl, made of valves positioned on the bottom of the mixing bowl to drain the cleaning water of the mixing bowl and of a water collection system of the mixing bowl, arranged for the connection to the drainage system, manufactured in stainless steel

CLEANING SYSTEM

Electro-pneumatically controlled cleaning system for the mixing bowl and the mixing arm, made of a cleaning system positioned on the cover.